Robotics & Automation

Robotics & Automation Products

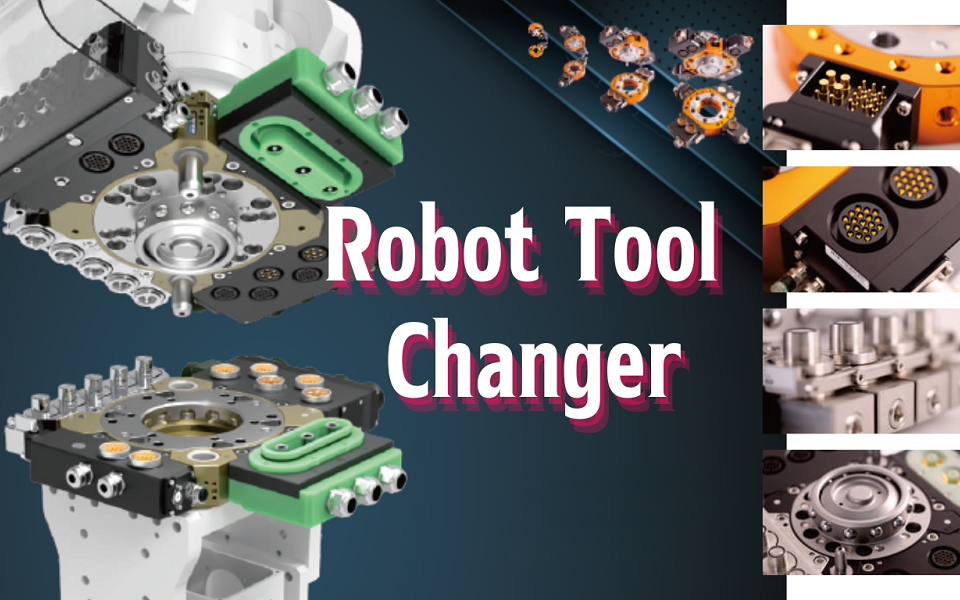

Robot Tool Changer

A flexible device which can help single industrial robot match with more end-effectors

.png)

ROKAE Collaborative Robots

Next-Generation Flexible Collaborative Robots ROKAE xMate Series.

ROKAE Industrial Robots

ROKAE Industrial Robots Faster, more reliable, more precise

Automation

Is a system that works through computer control.

Automation or automatic control, is the use of various control systems for operating equipment such as machinery, processes in factories, boilers and heat treating ovens, switching on telephone networks, steering and stabilization of ships, aircraft and other applications and vehicles with minimal or reduced human intervention. Some processes have been completely automated.

The biggest benefit of automation is that it saves labor; however, it is also used to save energy and materials and to improve quality, accuracy and precision.

The term automation, inspired by the earlier word automatic (coming from automaton), was not widely used before 1947, when Ford established an automation department. It was during this time that industry was rapidly adopting feedback controllers, which were introduced in the 1930s.

Automation has been achieved by various means including mechanical, hydraulic, pneumatic, electrical, electronic devices and computers, usually in combination. Complicated systems, such as modern factories, airplanes and ships typically use all these combined techniques.