SILICONES VS. POLYURETHANES

Posted 28 Apr 2023 11:24 | 1,962 views

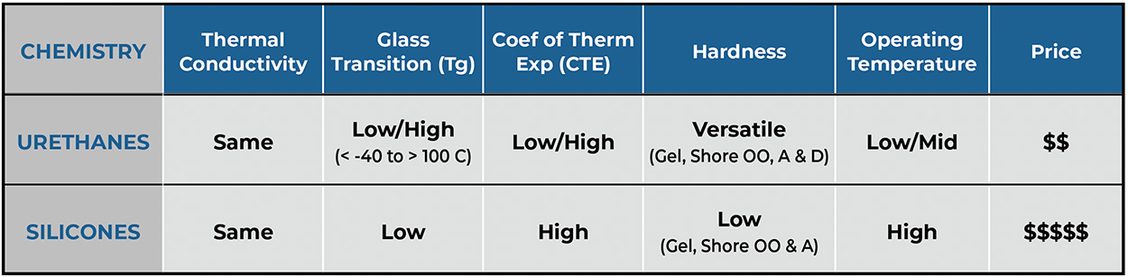

Which is best for your potting application?

.png )

While silicone potting has some advantages, polyurethanes work better in many applications. The main advantage of silicone compounds is their resistance to degradation at temperatures over 200°C, while offering a soft polymer. However, polyurethane’s thermal range can easily handle the operating temperatures of many industrial electronics, and its lower cost raw materials and application processes makes it a better option for a wider range of applications.

Why Replace Silicone Potting with Urethanes

8 ADVANTAGES OF REPLACING SILICONE POTTING WITH POLYURETHANES

1. MORE ECONOMICAL POLYMER:

lower cost of raw materials and application processes.

2. LOWER WATER VAPOR PERMEABILITY:

offers better protection of sensitive components against water migration causing

corrosion.

3. REDUCED OUTGASSING:

polyurethanes utilize different raw materials resulting in lower outgassing.

4. OPTIMAL OPERATING TEMPERATURE RANGE:

from -60°C to 150°C, with short excursions into higher temps.

5. BETTER BOND STRENGTH:

dependable adhesion to substrates and casings.

6. IMPROVED PHYSICAL ATTRIBUTES:

higher strength, elongation and abrasion resistance.

7. BETTER CHEMICAL RESISTANCE:

stands up to exposure to more chemical compounds.

8. WIDER FORMULATION LATITUDE:

polyurethanes can be formulated as soft as a silicone gel and as rigid as a highly

cross-linked epoxy.

source : epic resin