Classifications based on 3 different ESD models

Posted 20 May 2024 16:36 | 13,124 views

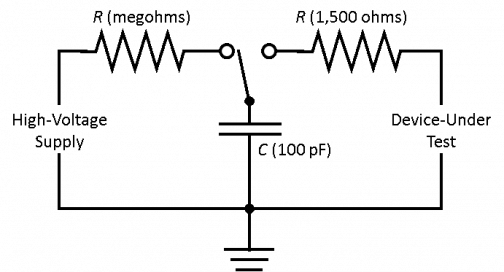

Human Body Model (HBM) Testing

Figure: https://www.esda.org/assets/268c33d236/Fig-1__ResizedImageWzUwNCwyNzJd.png

The most common model is the HBM. This model simulates when a discharge occurs between a human (hand/finger) to a conductor (metal rail). The equivalent capacitance is 100 picofarads (100 x 10^-12 Farads) and equivalent resistance is 1,500 ohms to simulate a human body. The typical rise time of the current pulse (ESD) through a shorting wire averages 6 nanoseconds (6x10^-9 s) and larger for a higher resistant load. The peak current through a 500-ohm resistor averages 463 mA for a 1,000-volt pre-charge voltage.

Per ESD-STM5.1-1998 Human Body Model (HBM)Component Level paragraph 4 Table 1-HBM ESDS Component Classification

| Class | Voltage Range |

| Class 0 | <250 volts |

| Class 1A | 250 volts to <500 volts |

| Class 1B | 500 volts to < 1,000 volts |

| Class 1C | 1000 volts to < 2,000 volts |

| Class 2 | 2000 volts to < 4,000 volts |

| Class 3A | 4000 volts to < 8000 volts |

| Class 3B | ≥ 8000 volts |

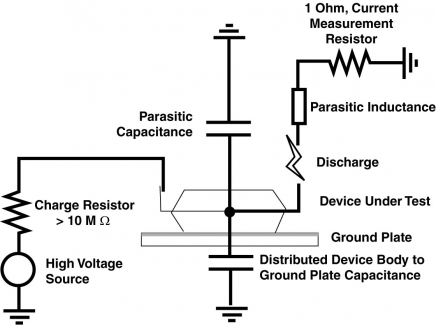

Charge Device Model (CDM)

Figure: https://www.esda.org/assets/2a5e5492fd/Fig-2-v2__ResizedImageWzQzNiwzMjVd.png

The most neglected of models that can compromise your ESD control program. Here, it is the ESDS device itself that becomes charged (sliding out of a tube/bag/sorter/etc) and when contacting a grounded conductor (table top/hand/metal tool) will discharge to that conductor and may result in damaging ESD. Using a 4 pF or 30 pF verification module which can simulate from 2 to 30 Amps peak current for non-socked and up to 18 amps for socketed devices.

CDM ESDS Component Classification

| Class | Voltage Range |

| Class C1 | <125 volts |

| Class C2 | 125 volts to <250 volts |

| Class C3 | 250 volts to <500 volts |

| Class C4 | 500 volts to <1,000 volts |

| Class C5 | 1,000 volts to <1,500 volts |

| Class C6 | 1,500 volts to <2,000 volts |

| Class C7 | > or = 2,000 volts |

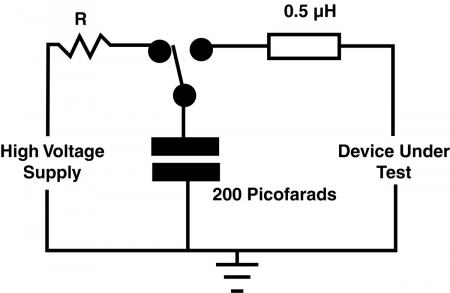

Machine Model (MM) Testing

Figure 3: https://www.esda.org/assets/6d8f9a9a6e/Fig-3__ResizedImageWzQ1MCwyOTNd.png

Testing components to the Machine Model (MM). The tests replicate MM failures and tell you the MM ESD sensitivity levels for your Devices. The criteria (200 pF @ a nominal 0 ohms).

7.1.2. Machine Model Sensitivity: A source of damage for the MM is a rapid transfer of energy from a charged conductor to the conductive leads of the device. This ESD model is a 200 pF capacitor discharged through a 500 nH inductor directly into the device with no series resistor. Due to the lack of a series current limiting resistor, this model approximates a voltage source. In the real world this model represents a rapid discharge from items such as, charged board assembly, charged cables, or the conduction arm of an automatic tester. The discharge itself is a sinusoidal decaying waveform with a rise time of 5-8 nanoseconds and a period of approximately 80 nanoseconds. Control to this model would entail knowing the ESD sensitive devices MM ESD component classification and keeping all voltages below their MM Classes voltage range.

MM ESDS Component Classification

| Class | Voltage Range |

| Class M1 | <100 volts |

| Class M2 | 100 volts to <200 volts |

| Class M3 | 200 volts to <400 volts |

| Class M4 | < or = 400 volts |

See ESD Association standards which establishes the procedure for testing, evaluating, and classifying the electrostatic discharge (ESD) sensitivity of components: ESD STM5.1-1998 Human Body Model (HBM)Component Level S5.2-1994 Machine Model ESD STM5.2-1998 Human Body Model (HBM) Component Level

Per ESD Handbook TR20.20 section 4.1.1 Determining Part ESD Sensitivity "The first step in developing an ESD Control Program plan is to determine the part, assembly or equipment sensitivity level under which the plan is to be developed. Although the requirements outlined in ANSI ESD S20.20 are effective for handling parts sensitive to 100 volts HBM or higher, the organization may choose to assess whether their items have a higher HBM sensitivity threshold or in other words, less sensitive to HBM events. In a case where a higher threshold has been determined, the organization may wish to tailor the contents of ANSI ESD S20.20, and incorporate a plan that is consistent with the part sensitivity assessment. If a contractual situation exists where the plan must be approved by both parties, the new sensitivity threshold and tailored requirements must be agreed upon.

The organization can use one of several methods to determine the ESD sensitivity of the products that are to be handled. Some of the various methods are:

- Assumption that all ESD products have an HBM sensitivity of 100 volts.

-

Actual testing of products using accepted test methods”

ANSI/ESD S20.20, for the Development of an Electrostatic Discharge Control Program for – Protection of Electrical and Electronic Parts, Assemblies and Equipment (Excluding Electrically Initiated Explosive Devices) Foreword “This standard covers the requirements necessary to design, establish, implement, and maintain an Electrostatic Discharge (ESD) Control Program for activities that: manufacture, process, assemble, install, package, label, service, test, inspect or otherwise handle electrical or electronic parts, assemblies and equipment susceptible to damage by electrostatic discharges greater than or equal to 100 volts Human Body Model (HBM). When handling devices susceptible to less than 100 volts HBM, more stringent ESD Control Program Technical Requirements may be required, including adjustment of program Technical Element Recommended Ranges.”

Per MIL-STD 1686 section 5.2.1.1 HBM [Human Body Model] sensitivity classification. “The principal source of ESD damage is the human body, as modeled by the HBM standards. HBM ESD sensitivity classification of parts shall be determined as follows: (a) At the discretion of the contractor, all parts shall be considered as HBM ESD sensitive. In this case, all parts may be classified as falling in the HSM Class 1-3 voltage ranges and included in the ESD control program.”

Cr. emit.descoindustries.com