Understanding the Vital Role of the Spindle Motor in Sycotec Machines

Posted 22 Mar 2024 11:14 | 2,111 views

Spindle motors in Sycotec machines: the heart of precision and efficiency in production.

Image source_ https://link.springer.com/article/10.1007/s00170-020-06069-0

In the realm of precision manufacturing The spindle motor is an important component. This is especially true in the context of advanced machinery. It plays an important role in various industries. From automotive to aerospace where high accuracy and efficiency are paramount. Among the many components that help keep machines running smoothly, The motor spindle is considered to be central. Let's dive into its importance and functionality.

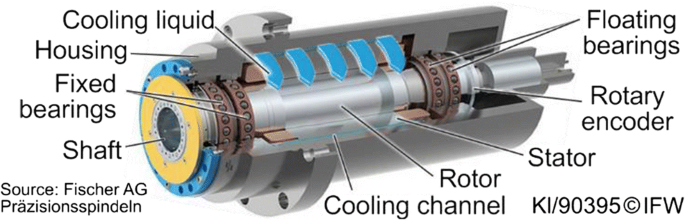

What is a spindle motor? The spindle motor is the heart of the machine. which rotates the cutting tool or workpiece with precision and accuracy. It acts as the driving force behind the machining process. It determines speed, torque and stability. This is critical to achieving the desired results.

-

High Precision: machines demand exceptional precision, and the spindle motor plays a pivotal role in delivering it. These motors are engineered to operate with minimal runout and vibration, ensuring that the machining process remains stable and accurate.

-

Variable Speed Control: Flexibility in speed control is essential to adapt to different machining requirements. Spindle motors in machines are equipped with variable speed control mechanisms, allowing operators to adjust rotational speeds according to specific tasks, materials, and cutting tools.

-

Torque Performance: Maintaining consistent torque throughout the machining process is vital for achieving uniform cutting forces and optimal surface finishes. Spindle motors are designed to deliver ample torque across a wide range of operating speeds, enabling efficient material removal and machining operations.

-

Thermal Stability: Heat generation during prolonged machining operations can adversely affect both the spindle motor and the workpiece. Advanced spindle motor designs incorporate features such as efficient cooling systems and thermal management mechanisms to maintain optimal operating temperatures and prevent thermal-induced deformation or damage.

-

Durability and Reliability: In industrial settings, reliability is non-negotiable. Spindle motors in machines are built to withstand the rigors of continuous operation, with robust construction, high-quality materials, and stringent quality control measures ensuring long-term reliability and durability.

The versatility of sycotec machines equipped with high-performance spindle motors makes them indispensable across various industries and applications, including:

- Precision machining of components for aerospace and automotive sectors.

- Mold and die making for injection molding and casting processes.

- High-speed milling of complex geometries in the medical device and electronics industries.

- Prototyping and rapid manufacturing in research and development environments.

The spindle motor stands as a testament to the relentless pursuit of precision, efficiency, and reliability in modern manufacturing. As a critical component of sycotec machines, it plays a pivotal role in shaping the future of industrial production, driving innovation, and enabling the realization of intricate designs and complex geometries. With continuous advancements in technology and engineering, the spindle motor continues to evolve, pushing the boundaries of what's possible in the realm of precision machining.

Image source_ https://www.cytec-systems.fr/en/cytec_high_speed_machining_equipment_motor_spindles.html

#การทำความเข้าใจบทบาทสำคัญของสปินเดิลมอเตอร์ในเครื่องจักร sycotec #motor #spindle #Machines