Use cases for industrial customers: dry cabinet

Posted 8 Mar 2024 13:09 | 1,663 views

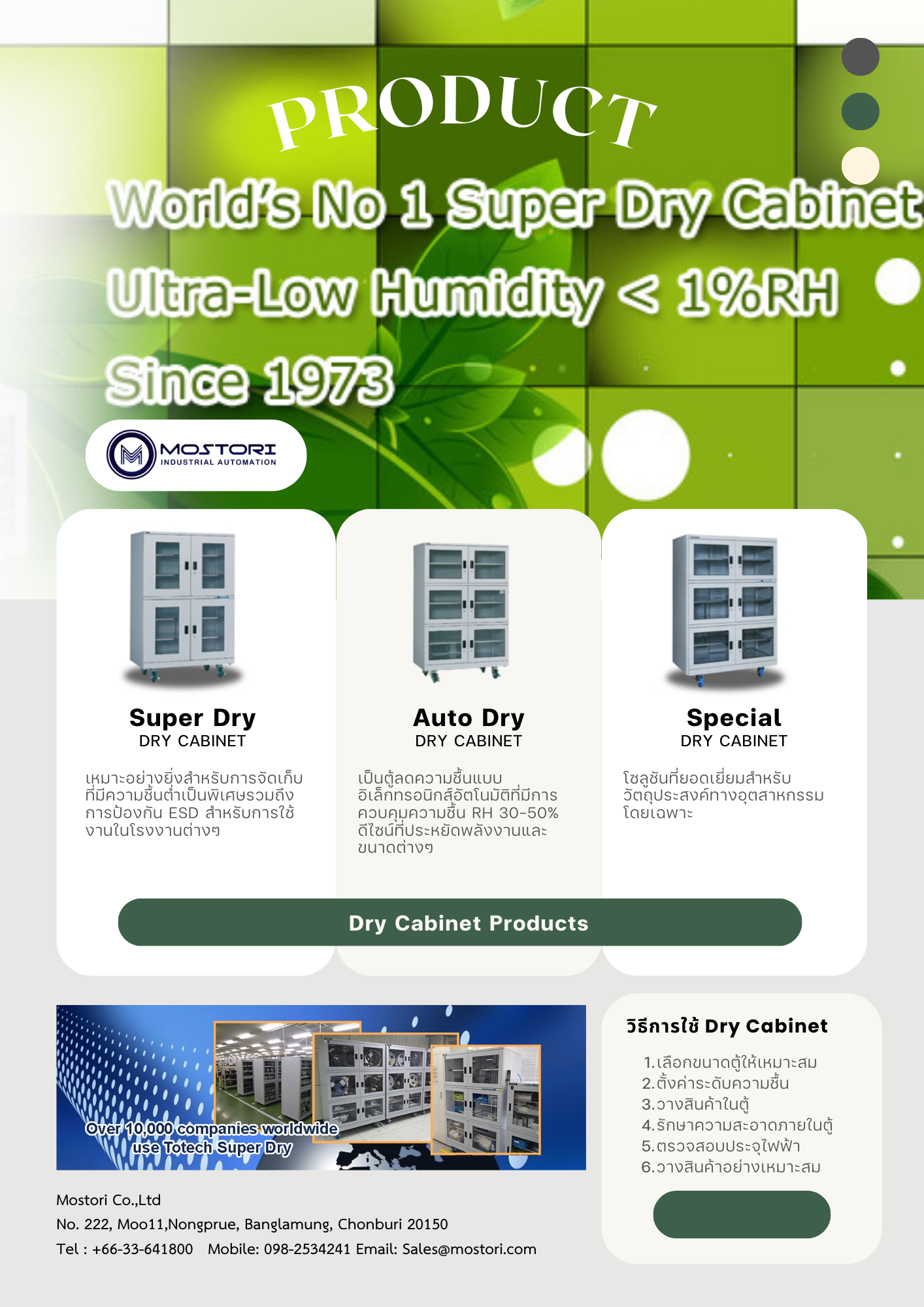

Dry cabinet, also known as desiccators, offer a controlled environment with low humidity, making them ideal for various industrial applications. Here are some specific use cases for Dry Cabinets by TOTECH in different industries.

- Electronics Manufacturing: In electronics manufacturing, sensitive electronic components and devices are highly vulnerable to moisture damage. Industrial customers in this sector use Dry Cabinets to store electronic components, circuit boards, and finished products to prevent moisture-related defects and ensure product reliability.

- Moisture-sensitive components (MSDs): Dry cabinets are crucial for storing and handling MSDs like circuit boards, integrated circuits, and other sensitive electronic components. They prevent moisture-induced damage like corrosion, electrical shorts, and component failure, ensuring product quality and reliability.

- Medical Device Manufacturing: Overall, Dry Cabinets supplied by TOTECH play a vital role in maintaining the quality, integrity, and regulatory compliance of medical devices during the manufacturing process. By controlling moisture levels and preventing moisture-related issues, these cabinets help ensure the reliability and safety of medical devices used in clinical settings and patient care.

- Biotechnology and Pharmaceutical Manufacturing: Laboratories and manufacturing facilities in the biotechnology and pharmaceutical industries require controlled environments for storing sensitive materials, reagents, and samples. Dry Cabinets are used to maintain low humidity levels to preserve the integrity of biological samples, pharmaceutical ingredients, and research materials, ensuring accurate experimental results and product efficacy.

- Semiconductor Industry: Semiconductor manufacturing involves extremely sensitive materials and processes that are susceptible to moisture contamination. Dry Cabinets are essential for storing semiconductor wafers, integrated circuits, and other critical components in a controlled environment to maintain their quality and functionality.

- Optical Instrumentation: Industrial customers in the optical instrumentation industry rely on precision optical components and instruments that can be adversely affected by humidity. Dry Cabinets are used to store lenses, mirrors, cameras, and other optical devices to prevent fogging, corrosion, and other moisture-related issues that could degrade performance.

- Precision Engineering: In precision engineering applications such as aerospace, automotive, and precision machining, maintaining tight tolerances and high-quality standards is crucial. Dry Cabinets help industrial customers store precision tools, gauges, molds, and machined parts in a moisture-free environment to prevent rust, oxidation, and dimensional changes that could affect product quality and accuracy.

- Food and Beverage Processing: In food and beverage processing facilities, maintaining proper storage conditions is essential to prevent spoilage, contamination, and quality deterioration. Dry Cabinets are utilized to store sensitive ingredients, packaging materials, and equipment in a moisture-controlled environment, minimizing the risk of microbial growth, chemical reactions, and product degradation.

These are just a few examples of industrial customer use cases for Dry Cabinets provided by TOTECH. Each industry has specific requirements and challenges, but Dry Cabinets offer a versatile solution for preserving the integrity and quality of sensitive materials in various industrial applications.

Data Sources: Totech website: https://www.totech.co.jp/en/

#ผู้จัดจำหน่ายในไทย #drycabinet #totech #superdry #Manufacturing