Better Life with Robots : xMate Series Collaborative Robots

Posted 1 Oct 2024 14:14 | 1,320 views

Discover how ROKAE xMate Series Collaborative Robots enhance production efficiency and safety with their innovative design and advanced technology.

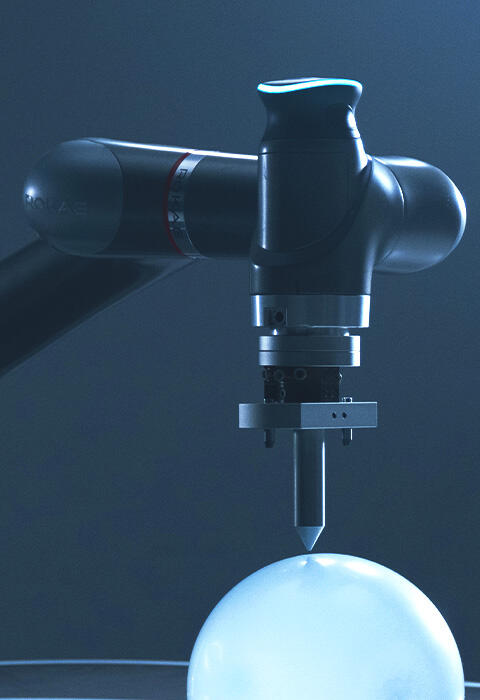

xMate Series Collaborative Robots A partner you can rely on in production

The xMate series brings a new level of innovation to collaborative robots with its cabinet-free design and built-in torque sensors in every joint. This unique design allows for greater flexibility, ease of use, and deployment across multiple sectors such as healthcare, new retail, commercial use, and more. With its focus on safety and superior performance, the xMate series is redefining how collaborative robots operate in modern industries.

Why Choose Collaborative Robots?

|

|

|

|

|

Extreme Safety

● Sensitivity improved by 10 times thanks to the collision detection by torque sensors

● More than 21 TÜV functional safety features, meets functional safety standards: ISO 13849-1, ISO 10218-1/PL d, Cat. 3; ISO 15066

● Dual-channel redundant monitoring of sensor information and an independently certified safety controller

● The position holding accuracy is better than ±0.1mm when power on and off, powered by suction contracting brake and dynamic feedforward compensation

Superior Performance

● Cutting-edge motion control technologies for industrial robots: OptiMotion, TrueMotion, and SyncMotion

● First-class robot path accuracy supported by dynamic feedforward compensation and dynamic modeling based on over 2000 parameters

● Payload capacity increased by 20% thanks to the customized motor drive control system

Compliant Flexibility

● Powerful yet flexible robot control based on force-position hybrid control framework

● Force control task efficiency improved by over 3 times through highly dynamic force control

● Fine grinding and precision assembly with no extension required thanks to built-in joint sensors and complete force control process kit

Ease of Use

● Direct teaching control with 1N based on point position and continuous trajectory

● Graphical programming interface with flowcharts enables users to get started within 1 hour

● Friendly development and open ecosystem support 100+ ecosystem extension tools of 5 categories

● Proprietary Rokae Studio offline programming software that supports the simulation for all models

● A control-cabinet-less design is available, reduceing system weight by 50% and allowing for fast installation and flexible deployment

Excellent Reliability

● Motion planning based on dynamics constraints delivers high performance, overload protection, and an extended service life

● 100+ design verification experiments, 20+ factory tests, and MTBF > 80,000 h

● IP67 protection level satisfies the demands of harsh industrial applications

Collaborative Robots

CR Series Collaborative Robots

|

|

|

|

| CR7 Series Payload : 7 kg Reach : 988 mm DOF : 6 |

CR12 Series Payload : 12 kg Reach : 1434 mm DOF : 6 |

CR18 Series Payload : 18 kg Reach : 1062 mm DOF : 6 |

CR20 Series Payload : 20 kg Reach : 1798 mm DOF : 6 |

CR-C Series Collaborative Robots

|

|

|

|

|

|

| CR7-C Series Payload : 7 kg Reach : 988 mm DOF : 6 |

CR12-C Series Payload : 12 kg Reach : 1434 mm DOF : 6 |

CR18-C Series Payload : 18 kg Reach : 1062 mm DOF : 6 |

CR20-C Series Payload : 20 kg Reach : 1798 mm DOF : 6 |

CR25/5-C Series Payload : 25 kg Reach : 1798 mm DOF : 5 |

CR17/5-C Series Payload : 17 kg Reach : 2047 mm DOF : 5 |

SR Series Collaborative Robots

|

|

| SR3 Series Payload : 3 kg Reach : 705 mm DOF : 6 |

SR4 Series Payload : 4 kg Reach : 919 mm DOF : 6 |

SR-C Series Collaborative Robots

|

| SR-C Series Payload : 5 kg Reach : 919 mm DOF : 6 |

These robots offer the latest in automation technology and provide the safety, efficiency, and flexibility needed to meet the demands of modern industrial applications

source : www.rokae.com / chatgpt.com

#Robot #Cobot #Rokae #industry