Non-cellular Elastomers A Safer, More Reliable Alternative to Foams for Next-generation E-Mobility Battery Packs

Posted 18 Sep 2025 10:20 | 678 views

Discover non-cellular elastomers for EV battery packs—safer than foams with superior vibration resistance, thermal runaway protection, and long-term reliability.

Non-cellular Elastomers: A Safer Alternative for Next-generation EV Battery Packs

As the e-mobility industry continues to grow rapidly, the safety and durability of battery packs have become a top priority for manufacturers. One of the biggest challenges lies in selecting protective and sealing materials for battery packs. Traditionally, foams have been widely used—but they come with limitations such as unpredictable expansion, void formation, and inconsistent performance.

To overcome these challenges, non-cellular elastomers have emerged as a safer, more reliable, and more consistent solution for next-generation battery packs.

Why Choose Non-cellular Elastomers?

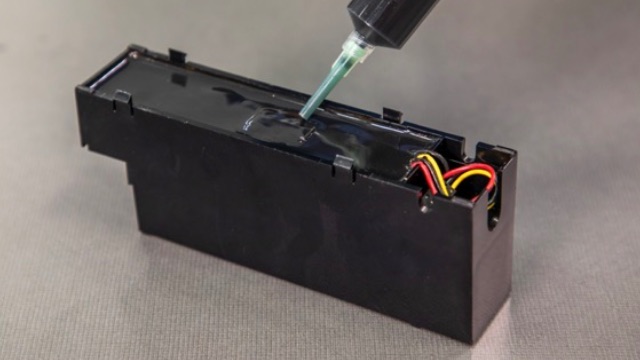

Unlike foams that may expand unevenly and leave gaps, non-cellular elastomers cure into a dense, uniform structure. This ensures consistent quality, reliable structural integrity, and long-term performance throughout the battery’s lifespan.

Key Advantages of Non-cellular Elastomers

-

Thermal runaway mitigation – contain and isolate flames, reducing propagation risk

-

Vibration and impact resistance – protects cells from mechanical stress and chafing

-

Moisture and chemical resistance – resist corrosion in harsh environments

-

Manufacturing consistency – predictable, consistent material every time

Proven Solutions for EV Battery Safety

Today, several non-cellular elastomer formulations have already been validated and adopted in the automotive industry. Each solution is designed to meet specific requirements of battery pack design, ensuring enhanced safety, reliability, and consistency.

Below are a few of our proven non-cellular elastomer solutions

|

|

|

| S7634: High-Performance Potting | S7633: UL 94 V-0 Potting Compound | |

|

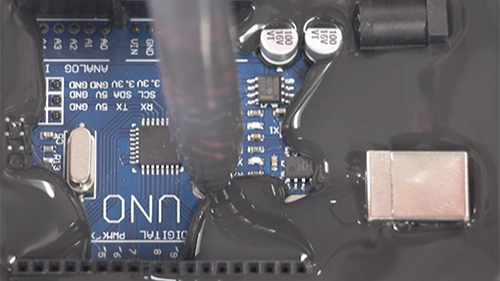

Uses: BMSs, DC/DC converters, GPS sensors

|

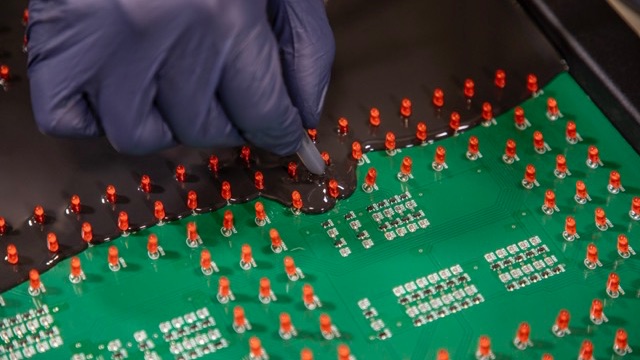

Uses: battery packs, other electrical applications

|

|

| Learn More. | Learn More. | |

|

|

|

| S7634: High-Performance Potting | S7633: UL 94 V-0 Potting Compound | |

|

Uses: BMSs, DC/DC converters, GPS sensors

|

Uses: battery packs, other electrical applications

|

|

| Learn More. | Learn More. |

Reach out to our experts to explore the right non-cellular elastomer solution for your battery design.

⇒ sales@mostori.com

⇒ 033-641800

⇒ www.mostori.com

.jpg)